You have a brilliant idea for a t-shirt. The design has been finalized. You can envision people donning it. But having that thought of an object made out of an original idea is still a considerable distance. The most important step is getting t-shirt manufacturers on board to give life to your idea.

This guide is the key to success. Follow our step-by-step instructions closely. You will become familiar with preparing your files and inspecting the final products. You are stepping into a billion-dollar custom clothing industry. The right partner is the winning factor. Ready? Let’s go.

Before You Contact a Factory: Your Checklist

It’s necessary to get yourself organized before calling a t-shirt factory for the first time. It will be a signal that you are serious. It will get you the right rates. You should prepare your materials first. This will help you save time and avoid confusion.

Finalize Your Design & Create a Tech Pack

The tech pack is the key document you will make. View it as the blueprint of your t-shirt. The factory will need this to understand your preferences. This will replace guessing with exact facts and results in fewer mistakes.

A good tech pack contains:

- Design pictures depicting the front, back, and side details.

- Exact color codes, usually Pantone (PMS) codes, for fabric and prints.

- Size measurements for each size you want (S, M, L, etc.).

- Fabric details, like material type and weight.

- Placement of all prints, embroideries, and labels.

- Instructions for custom labels or tags.

Decide on Fabrics and Blends

The touch of your t-shirt is as important as its look. 100% cotton is the most common fabric. This fabric may be ringspun for softness or combed for smoothness. Polyester blends are the best option for longevity and wrinkle resistance. The tri-blends are for that soft and vintage feeling.

The fabric weight must not be overlooked. It is described in Grams per Square Meter (GSM). A higher amount of GSM means a heavier and stronger t-shirt. On top of that, you can check out some unique specialty fabrics, like Pima Cotton, Bamboo, and Modal.

Determine Your Order Quantity (MOQ)

MOQ is the short form of the Minimum Order Quantity. This is the least amount a factory can manufacture for you in one order. The factories set up minimum ordering due to the fact that the machines, which need to be set up for newer designs, take time to do the setup.

Come up with a number that is realistic before you start negotiating. This number can be something like 100, 500, or 1,000 above units per design. With the numbers, a t-shirt factory can quote you properly.

How to Find and Vet the Perfect Partner

The choice of the partner manufacturer is the most critical one. A partner that is good delivers time, and money quality products; a bad one creates delays and costs money. This is a simple way to identify a trustworthy t-shirt factory.

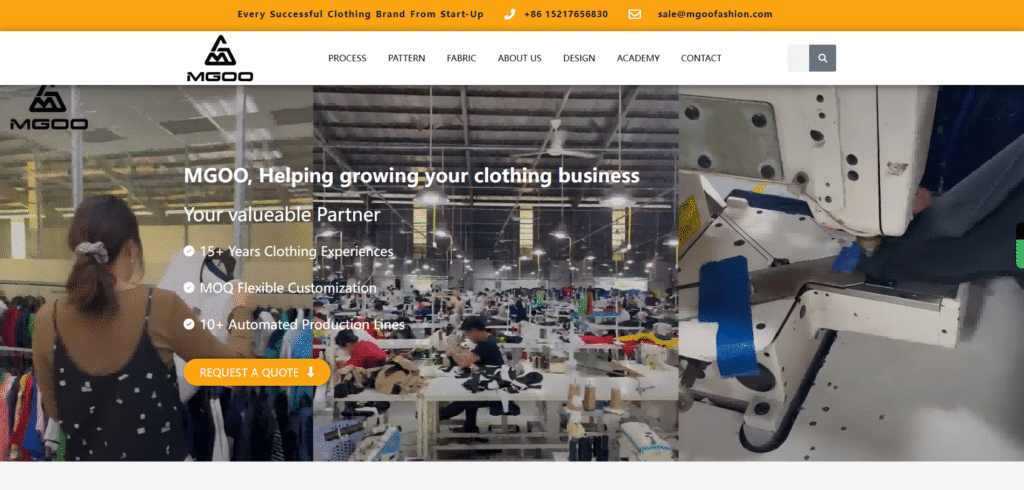

Where to Look for Manufacturers

The first thing that comes to your mind while thinking about how to look for a t-shirt factory is probably the internet. There are different platforms, and each of them brings different advantages to the table.

- Online Directories & B2B Marketplaces: Websites like Maker’s Row and Sewport that connect brands with manufacturers and are a good starting point.

- Targeted Google Searches: Be specific. Use terms like “custom t-shirt factory USA” or “sustainable apparel manufacturer” to find good matches.

- Social Media & Industry Forums: Platforms like LinkedIn and Reddit have groups where brand owners share tips.

- Research Lists: Some publications provide lists of top T-shirt manufacturers. These can be good research starting points.

The Vetting Checklist: 10 Critical Questions

Once you spot possible factories, you should investigate them. Asking the right questions demonstrates you are a professional. It also allows you to gauge their competency. Here are the ten significant queries to make any potential tshirt factory respond to.

- What is your MOQ per design and per color?

- Can you provide some examples or add photos of similar t-shirts you’ve made?

- What is your process and cost for manufacturing a sample?

- What is your standard production time after I give my approval on the sample?

- What are your payment terms (like 50% upfront, 50% when done)?

- Are you able to use my specific fabric and printing requests?

- What quality control measures do you have?

- Where is your factory located? What are the shipping costs?

- Who will be my primary contact person?

- Can you give references from other brands you are collaborating with?

Red Flags to Watch Out For

While the talk is in progress, be on the lookout for the signs of warning. The following red flags could signal a tough partnership in the future.

- Poor or slow communication.

- Won’t do a sample before bulk production.

- No real business address or registration.

- Insist on charge a 100% payment upfront for bulk orders.

The key to finding a full-service partner who helps you is a good tracker. An excellent clothing manufacturer will be straightforward and will respond to the questions easily.

Inside the Factory: The Manufacturing Process

Have you ever wondered how to make a t-shirt? By learning about the manufacturing process, you can plan your timeline better. This will also help you with your communication with the factory. Below is the step-wise look at the process.

-

Pattern Making & Grading

In the beginning, the factory creates a master pattern for one size. Then they use this pattern to create different patterns for all other sizes you need. This process is known as grading. -

Fabric Spreading & Cutting

Huge rolls of fabric are spread on long tables in many layers like clothing. Fibers are cut using machines or skilled workers for body, sleeve, and collar parts using the patterns. -

Sewing & Assembly

The cut pieces are taken to the sewing lines. Industrial sewing machines are used by workers to stitch the shirt together. This process also includes attaching sleeves, sewing side seams, and inserting the collar.

-

Printing & Customization

This is the space where your design is transformed into reality. Assembled shirts using methods like screen printing or direct-to-garment (DTG) are printed. It is at this stage that embroidery or other particular details are added. With the help of modern methods, some brands are after a puff print hoodie manufacturer to produce stylish 3-dimensional designs. -

Finishing & Quality Control

Each garment will be subject to a defect check. Workers will trim protruding threads, set labels, and ensure that the last product is according to your requirements. Some skilful T-shirt factory capabilities are available to thorough multi-point quality checks. -

Ironing, Folding, & Packing

At last, the t-shirts are pressed, folded neatly, and then packed in bags or boxes. They are now ready to ship to your warehouse or fulfillment center.

Decoding the Costs: What Determines Price?

The quote you receive from a t-shirt factory is subject to several variables. Understanding these components will help you to manage your finances efficiently. It will help you understand why the prices can vary. It is not just a plain shirt plus a print.

Here is a simple breakdown of what affects your cost per shirt.

| Cost Factor | Description | Impact on Price |

|---|---|---|

| Fabric Quality | Standard cotton vs. premium Pima, organic, or tri-blends. | High |

| Order Quantity | The higher the volume, the lower the price per unit. | High |

| Customization | Number of print colors, print size, multiple locations, embroidery. | Medium-High |

| Labor | The complexity of the t-shirt’s sewing and construction. | Medium |

| Labeling/Tags | Custom woven neck labels and hang tags vs. standard options. | Low-Medium |

| Shipping/Logistics | Domestic vs. international shipping and freight costs. | Varies |

Together, these aspects represent the overall price. A single print in one color on standard cotton is going to cost less than a sophisticated multi-location print on premium tri-blend fabric.

Expanding Your Product Line Beyond T-Shirts

After you build a good connection with the t-shirt factory, you can also adopt their skills on other products. This is a natural way for your brand to expand. Many t-shirt factories can actually make other clothes, which makes their offering even more attractive.

This will make growing much simpler. The usual expansions include sweatshirts and hoodies. By finding a flexible hoodie manufacturer who has already got the brand and quality standards, you will speed up the process while saving valuable time.

Frequently Asked Questions about Working with a T-Shirt Factory

Here are all-notch answers to questions that nascent brand owners usually have when they start out.

What is a realistic MOQ for a new brand?

It varies, but many factories in Asia have MOQs between 100-200 units per design and color. More miniature domestic factories might offer lower MOQs but are generally more expensive. The best is always to check the MOQ of a potential t-shirt factory before you begin negotiations.

Should I choose a domestic or overseas t-shirt factory?

It depends on what you want. U.S. companies have the shortest shipping times, the easiest communication, and a “Made in USA/UK” marketing pitch. But they are often costlier. On the other hand, overseas factories are generally cheaper when you order large quantities but they have longer lead times and are sometimes problematic in regard to communication.

How long does the entire process take?

Typically, the timeline is 8-12 weeks from the first contact to getting your order. This often involves 1-2 weeks for quotations, 2-3 weeks for sample production, and 4-6 weeks for the bulk production of the order. The timeline may shift based on the intricacy of your order and the factory’s schedule.

Can a factory help me with my design?

Some full-service factories can offer limited design help, but it’s not their main job. They’re only good at transforming a completed design into a final product (in a tech pack). The design itself should be developed by a graphic designer. Only after that, when the factory has its input, should they give technical hints.

Do I need to visit the t-shirt factory in person?

It is not always necessary, especially for new brands. A good vetting process, clear communication, and ordering a physical sample are often enough to ensure quality. In the case of very large orders or long-term partners, a visit can serve as a good opportunity for building a solid connection.