In 2026, the streetwear market has become extremely competitive. Every day, we see creative individuals shooting the query on how to make my own hoodie like the hottest brands. You might be interested in starting a fashion brand or just want to introduce your unique clothing line. Whatever be the case, a logo alone isn't enough. You need to delve into design, textures, and manufacturing processes to succeed.

Key Takeaways

- Design is Technical: A Tech Pack, not just a sketch is the first step to becoming a pro in hoodie design.

- Fabric Matters: To be a premium streetwear brand, you have to use heavyweight fabrics (350+ GSM) in 2026.

- Production Paths: Select Print-on-Demand if you want low risk or choose Cut & Sew for total customization.

- Quality Control: Stringent QC protocols are the backbone of the defect prevention strategy and brand reputation.

- Partnership: working with a well-established manufacturer is the best way to efficiently scaled your vision.

At Clothing Manufacturer Ltd, we have been in the production business for more than 10 years. We have a partnership with over 1000 fashion brands in all parts of the world. We have been instrumental in the growth of 500+ brands from having a simple idea to reaching full production. In this guide, we reveal our insider knowledge. We teach you how to get from your idea to a quality product, using a professional route.

Introduction: Transforming Your Hoodie Idea Into Reality

In recent years, there has been a greater demand for custom apparel. However, there is a huge disparity between a craft project and a real product. When our clients ask us "how to make my own hoodie", we provide different options. Are you sewing one of the pieces at home? Or do you want to build a brand around it?

If you want to build a brand, think from a producer's point of view. You need to be aware of your supply chain. You must also understand about the fabric sourcing and quality control. We are a team with 6 years of direct streetwear experience. We assist you every step along the way. We don't only make clothes. We create businesses. Hence this guide transports you through design, materials, and production.

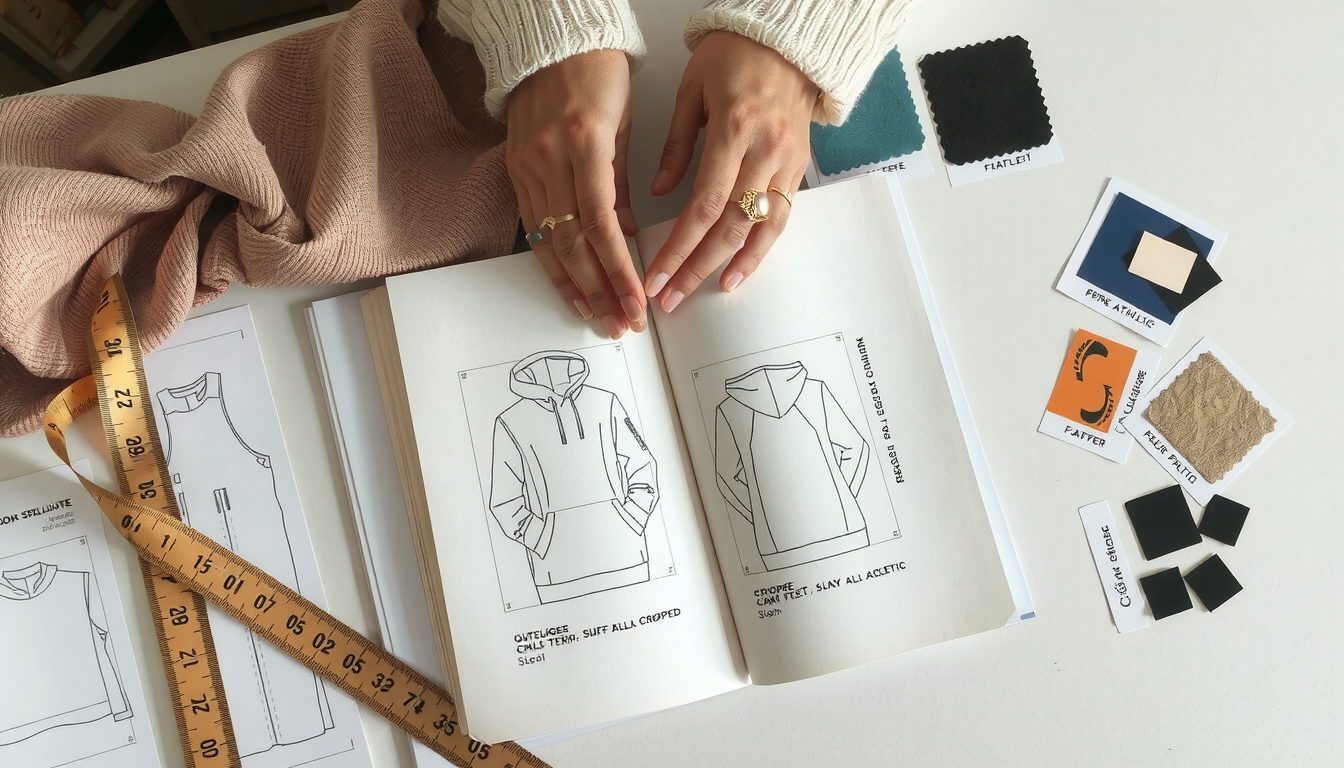

Step 1: The Design Phase – Beyond Just a Logo

A common misconception held by beginners is that design is only the graphic on the front. In the professional field, design is the complete plan for the whole garment. To learn how to make my own hoodie, first, think about the type of fit you like. Do you want an oversized party style? Would it be cropped-length? Slim fit for athletic cut? Make these decisions before your fingertips touch any fabric.

The Tech Pack

The essential tool you need to use here is Tech Pack. Your factory's instruction book. A Tech Pack is the thing no manufacturer can do without even the best one. The Tech Pack is complete when it has measurements, fabric details, color codes, BOM (Bill of Materials) where all items needed including fabric, zippers, and drawstrings are listed and other specifics.

| Tech Pack Component | Description |

|---|---|

| Flat Sketches | Technical drawings of the front, back and side views. |

| Measurements | Exact dimensions for every part of the hoodie (e.g., chest width, sleeve length). |

| BOM (Bill of Materials) | A list of all items needed including fabric, zippers, and drawstrings. |

| Color Codes | Pantone codes to ensure the dye matches your vision exactly. |

Visualizing the Product

Before we interfere with the fabric, we always visualize the final product. In 2026, tech is so precise that you can't help but be flawless. With 3D tools, you can see how the design fits in with the body. This step, which helps to catch errors early saves you money. As a starter, the online tools are very handy in trying out your own ideas. For instance, you can browse through Custom Hoodie – Sweatshirt Design Maker in 3D to visualize how your graphics would appear on the finished piece.

Step 2: Selecting the Right Fabric and Materials

You can decide the quality of your brand by the fabric you choose. While searching for how to make my own hoodie, you are likely to encounter the term GSM. It signifies the weight of the fabric measured in grams per square meter.

Understanding GSM

As for the streetwear market today, consumers associate a product's weight with its quality. For example, a regular-type hoodie can be 280 GSM. However, most premium brands use heavier fabric from 350 to 450 GSM. Heavyweight fabric is more stable and adaptable for reshaping purposes. To us, higher GSM is always the way to go. This is especially true for living in the luxury or high-end space.

Material Composition

- 100% Cotton: This is the most common fabric for a premium hoodie. It's breathable, soft to touch, and improves with age. Also, it is non-irritating for the skin.

- Cotton/Poly Blends: A mixture of cotton and polyester (majority 80/20) has a longer lifespan. It does not shrink as it also resumes better if you are going to use sublimation printing.

- French Terry vs. Fleece: It refers to the inner part of the fabric. Fleece is brushed and fuzzy. It provides heat. French Terry has its loops. Therefore it breathes better and is great for layers.

Sustainability Standards

Sustainability is now a basic requirement. Recent studies show that more than 60% of consumers prefer brands that are eco-friendly. We support GOTS (Global Organic Textile Standard) and OEKO-TEX certifications. Using GRS recyclable product certification helps your brand appear hip and mindful to shoppers.

Step 3: Production Methods – DIY vs. Professional Manufacturing

Now that you have the design and material, you should choose the method to make a hoodie. The method of how to make my own hoodie is determined by your budget and the goals you have.

Method A: DIY/Home Sewing

If you desire only one unique piece for you, home sewing is fun and rewarding. You will need to buy a pattern and source retail fabric. Besides that, you need a sewing machine that can run on thick knit fabrics.

Method B: Print-on-Demand (POD)

Print-on-Demand is a good option for those who are just starting and don't have to worry about inventory. You upload your designs to a platform. They print them on a blank hoodie when a customer orders. It's low risk, but the cost per unit is high. You also have to manage the fit and labels. Another option for small projects is to visit Custom Hoodies & Sweatshirts | Make Your Own Hoodie to learn about how POD services work.

Method C: Professional Custom Manufacturing (Cut & Sew)

Brands that are set up for serious business work on this line. Your factory makes your hoodie "Cut and Sew" for the factory choice. They create it from scratch. You utilize your own Tech Pack. As a result, you can get custom sizes, labels, and fabric choices. This is the method to take full control over the whole process.

If you seek to grow, you must have a professional hoodie manufacturer. A direct partner like us which works with you boosts volumen and keeps quality standards. We never overlook the pre-production sample stage. A pre-production sample is a prototype. We make it, you try it on and we make changes. We don't proceed to mass production until the sample is perfect. This way when you ask how to make my own hoodie, the answer is "perfectly".

Step 4: The Manufacturing Workflow and Quality Control

Acquainting yourself with the factory activities will help you plan your timeframe better. Professional manufacturing is a process that is stepwise and orderly. This reduces the probability of errors.

The Production Steps

- Pattern Grading: We start with your base size (like Large). We then calculate other sizes (S, M, XL) mathematically. The result is that the fit is uniform for all.

- Fabric Sourcing & Cutting: We get the exact fabric based on your Tech Pack. Layers of fabric are set, and it is precisely cut using laser or machine cutters.

- Decoration: This is the transformative point. This is where your art becomes reality. The decoration could be by screen print, DTG (Direct to Garment), puff print embroider, etc., before seaming.

- Sewing & Assembly: The skilled hands put all together. It also includes putting in the hood, pockets, and sleeves.

Quality Control (The Gold Standard)

Quality Control (QC) is the real difference between the brands that succeed and those that do not. We employ a technical "5-step QC production method." This assures that every unit is perfect.

- Raw Material Check: Checking if the fabric is free of holes or color issues before cutting.

- Inline Inspection: Monitoring the sewing quality during garment production.

- Semi-finished Check: Inspecting the garment before finalizing it.

- Finished Product Inspection: Doing a full review of the ready hoodie.

- Final Package Check: This includes confirming the proper folding, tagging, and bagging.

Strict QC is the assurance that the customer is getting their order correctly and in a good mood.

Conclusion: Branding with Your Hoodie

Determining how to make my own hoodie can give you a headache along the way. It is like a journey that takes you from idea to an actual product. Whether it is through a DIY route for fun or professional manufacturing for business, your priority should always be quality.

You will be on the path of success if you carry out these actions. Create a thorough Tech Pack. Select the best fabrics. Choose the right production partner. It is advisable to work with companies that have ISO 9001 and BSCI certifications. This ensures the perfect and ethical execution of your vision. The streetwear world is ready for your unique view of things.

FAQ: Frequently Asked Questions about Making Custom Hoodies

How much does it cost to make my own hoodie?

The cost largely depends on which method you choose. If you go with the DIY approach, material costs could be between $30 and $50. Print-on-Demand services will charge typically around $25 to $40 per unit. On the contrary, professional manufacturing hands down gives the best deal for brands. Although you must order a minimum quantity (MOQ), your unit prices will drop considerably. It usually ranges from $15-$25 depending on the complexity and quantity.

What is the best fabric for a high-quality hoodie?

For a trendy, heavyweight feel popular in 2026, we recommend 100% cotton. You might also opt for a cotton-dominant blend like 80% cotton, 20% polyester. Look for a fabric weight in the range of 350 GSM to 450 GSM. French Terry offers breathability while providing structure. Fleece, in turn, has a soft, warm inner layer texture.

Can I make my own hoodie without sewing skills?

Of course, you can. Just use Print-on-Demand services that allow you to print your designs on pre-made pieces. But if you want a unique fit, specific fabric, or other features, you would need clothing manufacturers to do the job. For instance, our company does the whole "Cut and Sew" process. You just have to cope with design and marketing while we manage the sewing.

What is a "Cut and Sew" hoodie?

"Cut and Sew" means the hoodie is built from raw material rolls. Your specific measurements and design guides the production. It is not simply printing on top of an existing product. This technique provides the best level of customization. Possibility to choose the fit, fabric, stitching type, and every little detail makes the product truly yours.

How do I find a reliable hoodie manufacturer?

Seek out manufacturers with decades of verifiable experience. Ideally, 10 years or more. Look for recognized certifications such as ISO 9001 or BSCI. These certifications ensure quality management and ethical labor practices. Always ask for samples first to verify their quality control. Make sure to discuss the specific design requirements with them about how to make my own hoodie.