Custom clothes are a wonderful option to communicate a message, create a brand or unite a team. They take a regular piece of clothing and make it one of a kind. Designing and printing custom clothes involves choosing a design, selecting a printing method, and finding a suitable partner for your project.

You will get through everything step by step with this guideline. We will discuss different methods of printing and how to make your artwork look best. At the end of the program, you will be able to transform your creativity into reality. We are going to mention the importance of working with a professional clothing manufacturer as one of the strategies to expand your business.

Grasping Different Printing Techniques

Choosing the right printing method is the most important decision you will make. It has an impact on the cost, durability, and feel of the product. Every method has its advantages. The best one will be determined by your requirements.

Let’s examine the most common options. We have created a simple table to assist you in comparing them quickly.

| Printing Method | Best For (Use Case) | Feel on Fabric | Durability | Cost-Effectiveness |

|---|---|---|---|---|

| Screen Printing | Large orders (24+), simple logos, brand merch | Slightly raised, durable ink layer | Very High | Low per item on large orders |

| DTG Printing | Photos, detailed art, single items, small orders | Soft, breathable, ink soaked into fibers | Medium | Good for small orders |

| Heat Transfer (HTV) | Team names/numbers, simple text, various fabrics | Smooth, vinyl layer on top | Medium | Good for small, simple orders |

| Puff Printing | Bold, textured designs that stand out | Raised, 3D, puffy texture | High | Higher than standard screen print |

Screen Printing: For Large Orders

Screen printing is a traditional and effective method. It works by forcing ink through a mesh screen onto a fabric. Each color in your design requires its own screen.

This technique produces bright, vibrant colors that are long-lasting. It is the most cost-effective option for large orders. This makes it ideal for corporate shirts, event apparel, and clothing lines. However, setting up each screen costs money. This makes it costly for small orders or designs with multiple colors. Professional clothing manufacturers offer high-quality screen printing as a primary service.

DTG Printing: For Detailed Artwork

Direct-to-Garment printing is similar to a standard printer, but for clothing. The printer applies water-based ink directly to the garment. The ink absorbs into the fabric.

DTG is ideal for photographs or designs with intricate details and colors. There are no setup fees for each color. This makes it suitable for small batches or individual items. According to experts in direct-to-garment (DTG) printing techniques, the ink is less vibrant on dark clothing. It may not be as durable as screen printing after multiple washes.

Heat Transfer Vinyl: For Simple Graphics

Heat Transfer Vinyl involves cutting a design from colored vinyl sheets. The cutout is placed on the garment and pressed with heat.

HTV is excellent for simple, bold graphics like text and logos. It is frequently used for team jerseys with names and numbers. The main drawback is that vinyl forms a plastic-like layer on the fabric. This can crack or peel after repeated washings.

Special Printing: For Adding Unique Textures

In addition to standard methods, special printing can give your custom printed clothes a distinct look. Puff printing employs a special ink that expands when heated. This results in a raised, 3D effect.

This is popular for modern streetwear and brand logos that must be noticed. This method is incredible for those who want fashionable clothing like a puff print hoodie. You can find out more by reading The Ultimate Guide to Puff Screen Printing.

Selecting Your Production Partner

Once you have determined which printing method you require, you must choose a partner to produce your clothing. There are three primary options. Each is appropriate for different goals and scales. Your decision will affect your costs, quality control, and level of involvement in the process.

Print-on-Demand Services

Print-on-Demand is ideal for entrepreneurs, artists, and anyone who only needs one or a few items. With this service, you link your designs to an online company. They manage all printing and shipping on your behalf.

The main advantage is the absence of upfront costs or inventory. You can Design personalized clothing online and the service will fulfill orders as they are received. The disadvantages are lower profit margins per item and less control over the final quality of your custom clothes.

Local Print Shops

Local print shops are ideal for small businesses, school teams, and event organizers. They are ideal for small to medium-sized orders where you want personalized service.

Working with a local shop allows you to see and feel samples before making a purchase. You also receive personalized customer service and contribute to the local economy. Their per-item prices may be higher than those of large corporations. They may be unable to handle extremely large orders.

Working Directly with Manufacturers

Working directly with a manufacturer is the best option for established brands and businesses that require large quantities. This option provides you with the most control over every aspect of your custom printed clothes.

You receive the lowest per-item cost and the highest quality control. You can also completely customize everything, including tags and labels. The primary difficulty is that manufacturers require large minimum orders. This necessitates a larger initial investment. For serious brands, collaborating with an experienced clothing manufacturer is critical for growth.

Designing for a Perfect Print

A brilliant idea can be ruined by a poorly designed art file. Preparing your design correctly is essential to ensuring that your final product appears professional. Taking a few moments to check your file can save you time and money.

Key Considerations for Your Design File:

- Vector vs. Raster: A vector file (such as or ) creates lines and shapes using mathematics. It can be resized to any size without sacrificing quality. This makes it ideal for logos. A raster file (such as or ) is composed of pixels. It is best for photos, but it can become blurry if enlarged too much.

- Resolution (DPI): Your file should be 300 DPI (dots per inch) at the size you want it printed for a clear, sharp print.

- Color Mode (CMYK vs. RGB): Computer screens display colors using RGB (Red, Green, Blue) light. Printers use CMYK (Cyan, Magenta, Yellow, Black) ink. To avoid unexpected color changes in your final print, always convert your file to CMYK.

- File Format: We recommend submitting your design as a vector file (, , ) or a high-quality with a transparent background.

From our experience, the most common issue we encounter is low-quality artwork from a screenshot. To avoid a pixelated, unprofessional result on your custom printed clothes, always use the original, high-quality source file. A good partner will help you create the best custom clothing for any occasion.

The Step-by-Step Procedure

Now that you understand the essential components, let’s combine them. Here is a simple guide to bringing your custom printed clothes to life.

- Step 1: Finalize Your Concept & Design: Begin with a clear objective. Who is this clothing intended for? What message do you hope to convey? Complete your design concept.

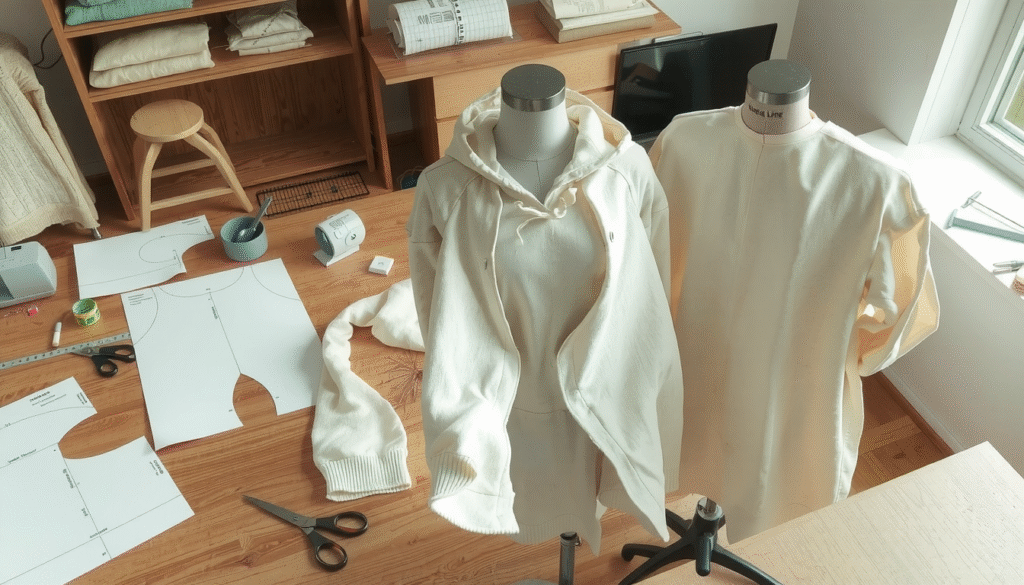

- Step 2: Choose Your Clothing: Select the type of clothing (t-shirt, hoodie, hat), the material (cotton, polyester, blend), and the color that will best complement your design.

- Step 3: Choose Your Printing Method & Partner: Using the information provided above, decide on the best printing method and production partner for your budget, quantity, and design.

- Step 4: Submit Your Artwork & Approve the Sample: Send your print-ready file to your partner. They will send you a digital proof showing how the design will look on the clothing. Examine it thoroughly.

- Step 5: Production & Quality Check: Once you approve the sample, your partner will begin printing your order. A good partner will have quality control measures in place to ensure consistency.

- Step 6: Delivery: Your completed order is shipped to you. It’s time to enjoy your new custom printed clothes!

Conclusion: Wear Your Vision

Creating custom printed clothes is a gratifying process that allows you to transform an idea into a tangible product. By understanding various printing methods, preparing your design for success, and selecting the right partner, you have complete control over the outcome.

Whether you are creating a single shirt as a gift or launching a full clothing line, these steps provide a clear path forward. You now have the expert knowledge to proceed from concept to creation with confidence. Go ahead and begin creating the custom printed clothes that will carry your vision into the world.

Frequently Asked Questions

What is the most durable printing method for clothing?

Screen printing is generally regarded as the best for withstanding multiple washes. The ink cures and forms a strong bond with the fabric. This makes it resistant to fading and cracking over time.

Can I order just one custom printed shirt?

Yes! This is an ideal application for Direct-to-Garment printing, which is offered by many Print-on-Demand services. They specialize in single-item orders with no minimum quantity. This makes getting just one shirt simple.

How much does it cost to have custom clothes printed?

The cost varies greatly depending on the printing method, clothing quality, number of colors in the design, and order quantity. A single DTG shirt could cost between $20 and $30. A large screen-printed order could reduce the per-shirt cost to less than $10.

What file format is best for t-shirt printing?

A vector file (such as , , or ) is ideal, especially for logos and text. It is infinitely scalable without losing quality. For photo designs, a high-resolution (300 DPI) PNG with a transparent background is the next best option.

How can I ensure that the colors on my shirt match my design?

To achieve the most accurate colors, ensure that your design file is in CMYK color mode. This is the mode used by printers. If precise color matching is required (for example, for a brand logo), provide Pantone color codes to your printing partner. Before full production, always approve a digital or physical sample.