In streetwear culture, one of the most contested items is the Fear of God Essentials hoodie. This piece is still a must-have for many streetwear enthusiasts around the world as we arrive at the year 2026. But there is a question that so many people are haunted by: who makes essentials hoodie? The answer entails more than just a brand name. It encompasses various manufacturing standards, fabric weights, and where the products are made worldwide.

Important Points to Remember

- Company Origin: Essentials is a line offered under the Fear of God umbrella. The line was launched by Jerry Lorenzo with the goal of providing easy-to-wear, timeless styles at a reasonable price.

- Production Locations: While designing happens in Los Angeles, most of the making takes place in Vietnamese and Chinese factories that are famous for high-quality knitwear.

- Material Standard: The heavy feel comes from thick fleece. Reputable manufacturers produce this fleece with a grammage between 380gsm and 480gsm (Grams per Square Meter).

- Fineness: Authentic products have specific wash tag fonts. The fashion brand also uses 3D silicone logos and a structured, double-lined hood.

- Production Regulations: Quality control depends on a rigorous checking system. Top manufacturers use both pre-shrinking and color fastness tests.

The Brief Reply: The Company and the Place of Manufacturing

If you want to know who makes essentials hoodie, there are two parts to the answer. The first is the designer, and the second is the one who actually makes it. The brand is part of Fear of God. This is a luxury streetwear brand that was created by Jerry Lorenzo in Los Angeles. The goal of the Essentials collection is to link high fashion with casual modern clothing. It focuses on uncluttered styles and natural shades.

The creative work is done in the US, but the production is global. In recent times, the line has moved production to Asia. Much of the stock for the hoodies comes from Vietnam and China. Industry experts often cite China's Ningbo region as a primary destination for advanced knitting and heavy fleece production.

While some say that western factories are the only place to produce high-end streetwear, this is not true. Factories are selected by their standing and must be in line with strict requirements. This global network, in turn, assists the brand by securing supplies for their flagship collections. This is made visible on the company's new release page. Essentials, as opposed to the Mainline collection, which may state "Made in USA" or "Made in Italy," uses Asian factories. The price is thus lower while quality is still good.

An Inside Look at the Essentials Production: A Manufacturer's View

With a decade specializing in fashionable clothing, we have a more profound perspective on clothes. We approach the question of who makes essentials hoodie by looking at the technical particulars. The popularity of this hoodie is not an accident; it is the result of cutting-edge technical design.

This hoodie is made with a thick cotton-blend fleece fabric. This fabric contains 80% cotton and 20% polyester most of the time. Sometimes, it is 100% cotton French Terry. The polyester serves a purpose. It strengthens the fabric, lessens shrinking, and helps the garment keep its shape.

A key measure is GSM (Grams per Square Meter). Our collaboration with over 500 successful brands has taught us many things. Normal hoodies weigh between 280gsm to 300gsm. The Essentials hoodie goes much higher, up to 480gsm. The sheer weight of this fabric creates the boxy street style look that is so beloved by the crowd. It is not clingy, so it creates volume.

This is how a common hoodie contrasts with premium streetwear like Essentials:

| Feature | Standard Retail Hoodie | Essentials Style Hoodie |

|---|---|---|

| Fabric Weight | 280gsm – 300gsm | 380gsm – 480gsm |

| Fit | Slim or Regular | Oversized, Boxy, Dropped Shoulder |

| Hood Structure | Single layer, often floppy | Double-lined, stands upright |

| Cuff Ribbing | Loose, loses elasticity | Tight, high-tension knit |

The Importance of Heavy Fleece and French Terry

Choosing the right fabric is key to determining the longevity of the product. Heavy fleece gives off a sense of bulk, which is often perceived as premium quality and provides good insulation against the cold. More than that, it reduces the chance of "torquing." That happens when the side seams twist after a wash. It is far less of an issue with heavy fleece than with lightweight materials.

Another option is French Terry, which is used in some warmer collections. It is not as fuzzy on the inside as fleece. Instead, it has a loop-back texture. It is breathable but still heavy. These garments are often finished with special washes like sun-fading or enzyme treatments that make them look vintage right away.

A Peek Behind the Curtain of Making Top-notch Hoodies

Finding out who makes essentials hoodie starts with looking at their manufacturing process. With six years in streetwear clothing, we can show you the manufacturing process. Making such a good garment is not easy. It is a refined industrial process.

The process begins with sourcing. For the best results, manufacturers will typically use GOTS-certified cotton. This ensures the cotton is organic, environmentally friendly, and gentle on the skin. The preliminary stage involves spinning yarn, which then goes through knitting into fabric rolls. The next step is dyeing, a crucial phase that determines color fastness.

We use a "5-step QC production method" in our own facilities. This method is implemented to prevent common defects. The stages include checking raw fabric, monitoring cutting precision, inspecting sewing lines, verifying sizing, and a final visual check before packaging. This is critical for heavy items. Thick fabric is more difficult to sew and requires special heavy-duty needles and machines to prevent skipped stitches.

At this level, ISO 9001 and BSCI certifications are very important. These ensure the factory runs smoothly and employees are treated well. When a brand grows to the size of Fear of God, stable production rates are vital.

For entrepreneurs of new brands, the obstacle is to find a factory that can match this quality. Finding a specialized hoodie manufacturer that is knowledgeable about heavy fabric and boxy cuts is the first vital step. We've connected with over 1000 global brands. The ones that truly succeed right from the start understand these technical details and prioritize them.

Spotting Fakes: Real vs. Counterfeit

Many people looking for who makes essentials hoodie are driven by the fear of buying a counterfeit product. The replica market is flooded today, and some are hard to tell apart by sight. A fundamental difference is that fakes, while cost-efficient, always make technical mistakes during production.

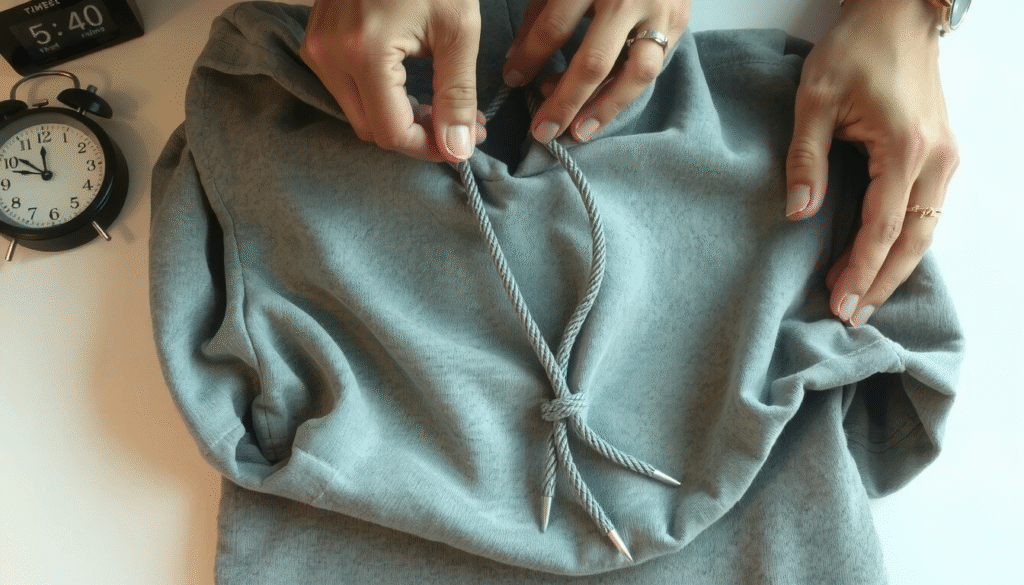

To identify a fake, observe three major zones:

- The Wash Tags: Real tags have specific fonts and spacing. Fakes often use generic fonts that look overly bold or condensed. The 'Made in Vietnam' or 'Made in China' text should be clear and distinct.

- The Logo Appliqué: The Essentials logo is often a 3D silicone heat transfer. On a real hoodie, it is matte and smooth with clean edges. On fakes, it often looks shinier, has jagged glue edges, or peels off easily.

- The Hood Structure: This is the telltale sign. Genuine hoodies are made of heavy material. The hood is double-lined and can stand up by itself. Fakes use cheaper, lighter fabric, which causes the hood to be floppy and lifeless.

Fakes fail for simple economic reasons. Using 400gsm cotton material is costly. Using pre-shrunk fabric is expensive. Counterfeiters skip these steps to maximize profits. We at Clothing Manufacturer Ltd stress that true quality cannot be faked. It requires high production standards and premium materials. When a customer holds a genuine article, they are feeling the result of a detailed and precise manufacturing process.

Frequently Asked Questions (FAQ)

Is Fear of God Essentials made in China?

Yes, most of Fear of God Essentials is made in China. This happens in areas famous for high-quality textile production. Some products are also produced in Vietnam. This differs from the Mainline Collection, which is often made in the USA or Italy. The location is not a compromise on quality, as it utilizes specialized factories capable of producing high-volume, quality fleece.

Who owns the Essentials brand?

Essentials is owned by Jerry Lorenzo. It was created as a subsidiary of his luxury streetwear brand, Fear of God, in 2018. The brand was intended to bring a more accessible price point and classic wearables to the market, diverging from the avant-garde Mainline collection.

Why is the Essentials hoodie so heavy?

The Essentials hoodie has made a name for itself because of its weight. It is made using high-GSM (Grams per Square Meter) fleece, which is usually between 380gsm and 480gsm. This heavy fabric creates the desired structured, boxy shape that doesn't cling to the body. This is a characteristic feature of high-grade streetwear.

How can I tell if my Essentials hoodie is authentic?

To identify the genuineness of the product, first check the wash tag. Look for the correct font and material composition, which is generally 80% cotton and 20% polyester. Also, inspect the rubberized logo for clean edges; it should not be peeling. Furthermore, real hoodies have a double-lined hood that stands up on its own. Fakes often use a single layer or lighter fabric that falls flat.

Does the Essentials hoodie shrink after washing?

Like most high-cotton garments, the Essentials hoodie can shrink if not cared for properly. However, reputable manufacturers use pre-shrunk fabric to minimize this. To maintain the fit and the quality of the rubberized logo, we recommend washing in cold water and air drying. Avoid high heat in the dryer.