In 2026, custom gifts are everywhere on social media. Few are as popular as the "Kiss Hoodie." This trend covers a hoodie in lipstick marks. People often arrange them to form initials or a heart. It is a sweet gesture that partners love. But many of these projects fail after one wash. The lipstick smears, fades, or ruins the fabric. This happens because regular makeup is not made for clothing.

Key Takeaways

- Fabric Choice Matters: Use a hoodie with at least 80% cotton. This helps the color soak into the fibers correctly.

- Use the Right Medium: Mix textile medium with your lipstick or use fabric paint. This is crucial for a design that survives washing.

- Heat Setting is Mandatory: You must use heat to cure the color. Use an iron or heat gun. This is a standard step in professional clothing production.

- Preparation is Key: Always wash the hoodie first. This removes factory chemicals. Use a cardboard insert to prevent bleed-through.

- Follow a Quality Check Process: Inspect your stencil and how hard you press. This helps you avoid messy edges.

Introduction: The Viral Trend Meets Professional Quality

The "Kiss Hoodie" has remained a popular gift idea well into 2026. It is personal, creative, and eye-catching. But there is a big difference between a hoodie that looks good for a video and one that lasts for years. Many DIY fans find that their hard work disappears after the first wash. This happens because most tutorials ignore basic fabric science.

At Clothing Manufacturer Ltd., we approach this differently. We have over 10 years of production experience in the clothing industry. We work with more than 1,000 international fashion brands. We understand how fabric and color work together. We have spent years perfecting streetwear and hoodies for global markets. We know that durability comes from proper preparation and finishing techniques.

In this guide, we will apply our industrial "5-step quality check production method" to this fun DIY project. We want you to create a gift that looks professional and stands the test of time. Whether you are making this for a partner or testing a design for a streetwear line, these steps will ensure high-quality results. Learning how to make a kiss hoodie correctly means combining creativity with manufacturing logic.

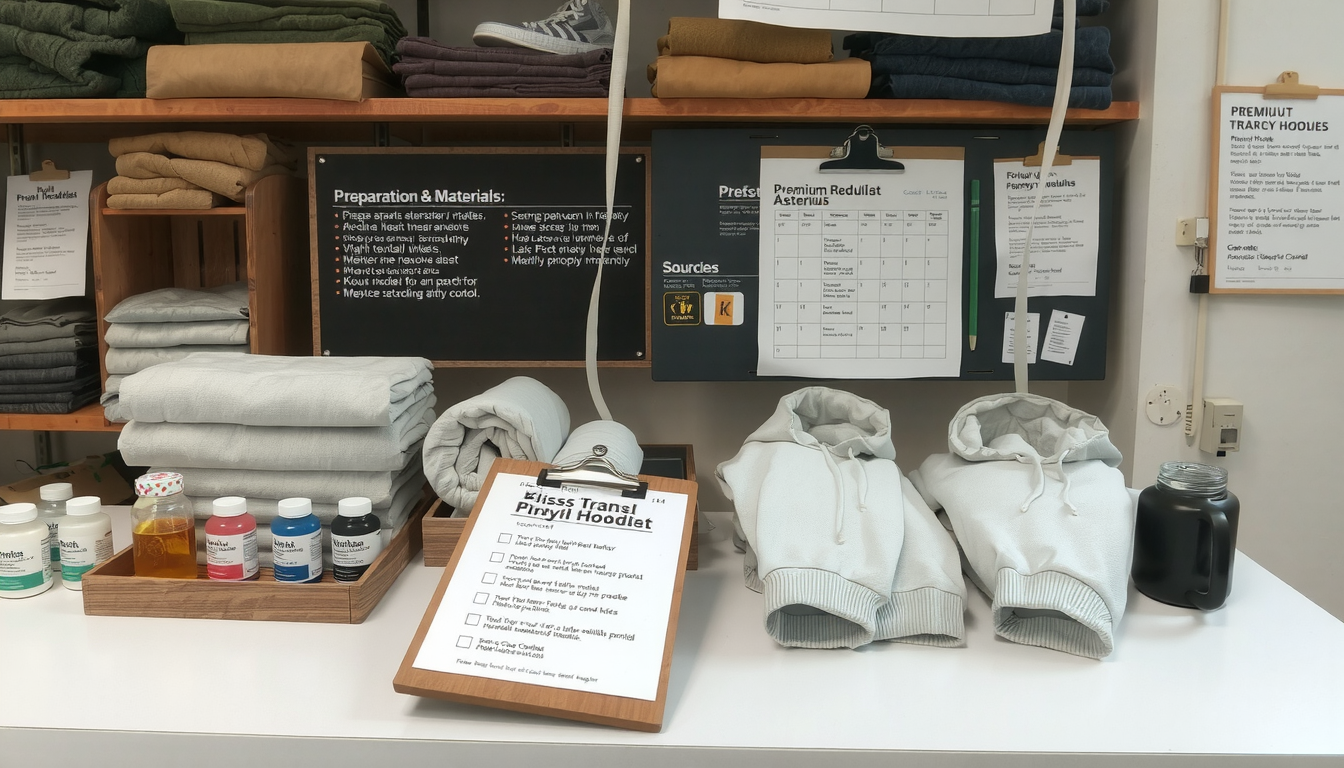

Phase 1: Preparation and Materials

The most common mistake is starting with the wrong materials. In professional manufacturing, material sourcing is the first step of quality control. If the base is poor, the art will not stick.

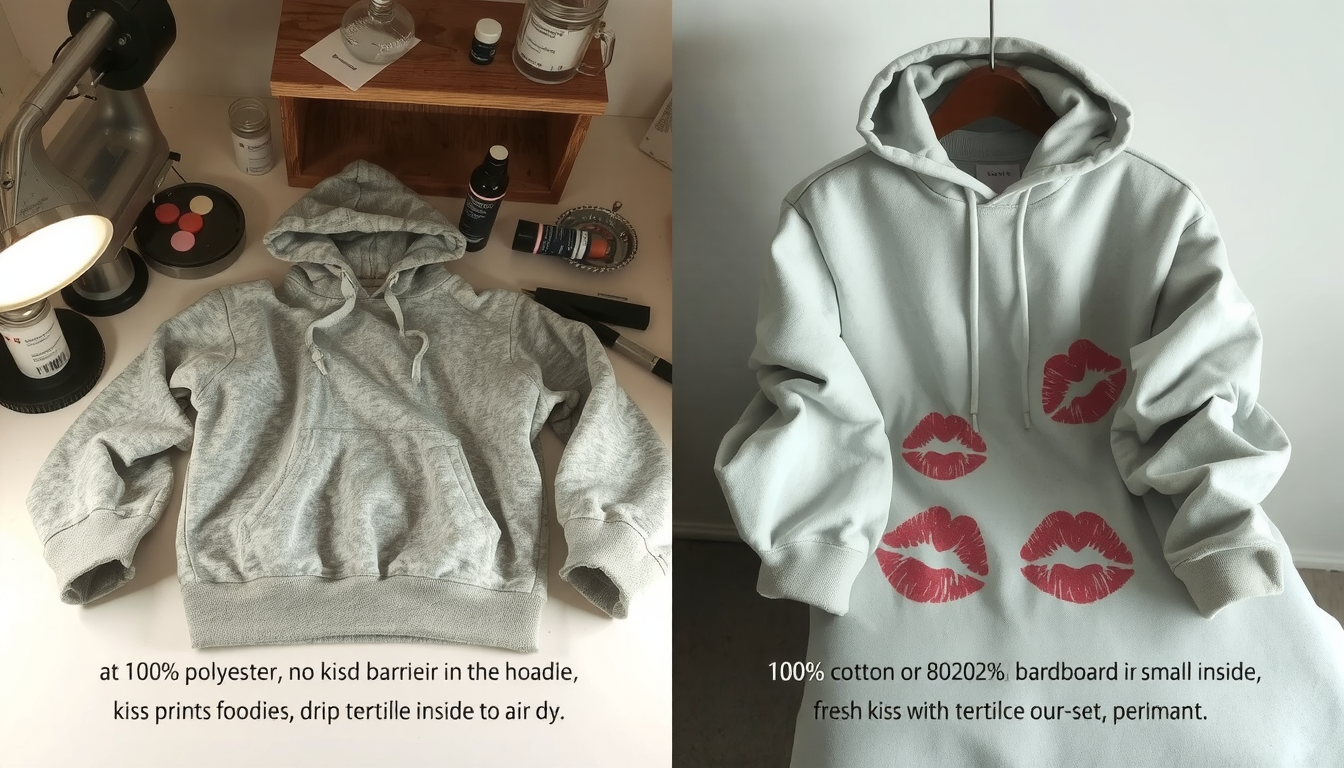

Choosing the Base Garment

You need a hoodie that can absorb color. Synthetic fibers like polyester are like plastic. They repel oil and water. This causes lipstick to sit on top and smear easily. We recommend a hoodie that is 100% cotton or a high-cotton blend. At least 80% cotton is best.

If you are a designer looking to produce these in bulk, finding the right blank garment is vital. You should work with a professional hoodie manufacturer to ensure the fabric weight is heavy enough. A heavier fabric provides a flat, stable surface for the kiss marks.

The "Paint" Selection

This is where the challenge lies. Real lipstick is oil-based. In the laundry, detergent attacks oil. It washes your design away. Fabric paint is permanent but looks flat. It lacks the texture of a real kiss.

To solve this, we suggest a hybrid approach. You can mix a "Textile Medium" with a highly pigmented lipstick. You can find textile medium at art stores. Or use fabric paint applied to your lips. Make sure it is non-toxic first. You can also use a stamp. For the most authentic look that lasts, seal regular lipstick with a heavy-duty fabric fixative.

Essential Tools List

To work like a pro, you need the right setup. Here is what we use in a simplified studio setting:

- Masking Tape: For creating crisp, clean borders.

- Cardboard: To place inside the hoodie. This prevents the "kiss" from bleeding through to the back.

- Heat Gun or Iron: Essential for the curing process.

- Fixing Spray: To seal the design.

| Amateur Materials | Professional Materials | Result Difference |

|---|---|---|

| 100% Polyester Hoodie | 100% Cotton or 80/20 Blend | Cotton absorbs color; poly repels it. |

| Oily Lipstick Only | Lipstick + Textile Medium | Medium turns makeup into paint. |

| No Barrier | Cardboard Insert | Prevents ruining the back of the hoodie. |

| Air Dry | Heat Set (Iron/Heat Gun) | Heat makes the design permanent. |

Phase 2: How to Make a Kiss Hoodie Step-by-Step

Now we move to production. In our factory, we follow strict steps to ensure every unit is identical. You should do the same for your single unit. This ensures it looks intentional and high-end.

Step 1: Pre-Treatment and Protection

New clothes often contain "sizing." This is a chemical stiffener used during manufacturing. It keeps clothes wrinkle-free during shipping. You must wash and dry the hoodie before you start. This removes the chemicals. It also shrinks the fabric slightly. This ensures your design does not warp later.

Once dry, slide a piece of thick cardboard inside the hoodie. Smooth the fabric over it. This provides a hard surface to press against. It helps capture the fine lines of your lips. It also protects the back layer of the hoodie from stains.

Step 2: Creating the Stencil

Decide on your layout. A simple rectangle or square is the most popular choice for the "Kiss Hoodie" trend. Use masking tape to mark off this area. Press the tape down firmly. This prevents color from bleeding under the edges.

If you want to do initials or complex shapes, you might need a paper stencil. For creative stencil ideas and letter templates, you can refer to resources like How to make kisses hoodie for Your Loved One (kisseshoodie.com). These offer guidance on layout preparation. Ensure your stencil is centered. In our factory, we use laser alignment. But a simple ruler works well for home projects.

Step 3: Application Technique (The Quality Check Approach)

This is the fun part, but it requires focus. If you are using fabric paint, apply a thin layer to your lips. If using lipstick, apply it heavily.

- Technique: Press your lips firmly onto the fabric inside the taped area. Do not wiggle. Just press and pull back.

- Density: Do not overcrowd the kisses immediately. Space them out first. Then fill in the gaps. This creates a balanced look.

- Cleanliness: Wipe your lips and re-apply fresh color every 3-4 kisses. This ensures the color remains vibrant. It does not look muddy.

- Edges: Make sure some kisses go over the masking tape. This creates a satisfying "cut-off" effect when you peel the tape. It makes the shape look very sharp.

Step 4: Removing the Stencil

Do not wait for the paint to be 100% dry before peeling the tape. If the paint is fully dry, it might bridge over the tape. It could peel off the fabric. Remove the masking tape carefully while the color is still slightly tacky. Pull the tape away from the design at a 45-degree angle. This reveals your crisp, straight lines.

Phase 3: Curing and Setting (The Secret to Durability)

This phase separates a beginner project from a professional one. Learning how to make a kiss hoodie involves understanding curing. Curing is the chemical process where the color bonds with the fabric fibers. Without this, your design will wash out.

Heat Setting

In professional production, we use large tunnel dryers to cure prints. At home, you can use a household iron or a hair dryer.

- Let the kisses dry completely. Wait at least 1 hour.

- Place a thin cloth or parchment paper over the design. Do not iron directly on the lipstick or paint.

- Set your iron to the "Cotton" setting. Do not use steam.

- Press the iron over the design for 3 to 5 minutes. Keep it moving slightly to avoid scorching.

The heat melts the binders in the paint or medium. This locks the color into the cotton fibers.

Sealing

If you used real lipstick without a textile medium, heat setting alone might not be enough. You should spray a clear fabric fixative over the design. Apply thin, even coats. Allow it to dry between coats. This adds a protective layer against water and friction.

The Wash Test

We always advise our clients to wait 72 hours before the first wash. This allows the chemical bonding process to fully stabilize. When you do wash it, turn the hoodie inside out. Use cold water. This reduces friction on the design.

Common Mistakes to Avoid (Quality Control)

To ensure your project meets the standards of Clothing Manufacturer Ltd., we recommend running a quick mental check. This is based on our "5-step quality check production method." Avoiding these common errors will save your garment.

- Skipping the Pre-Wash: If you do not wash the hoodie first, the paint sticks to the chemical coating, not the fabric. It will peel off later.

- Using Heavy Oil Lipstick: High-gloss or super-moisturizing lipsticks are the hardest to set. Matte lipsticks or fabric paints work much better.

- Applying Too Much Pressure: Pressing too hard can cause the lipstick to smudge. This loses the detail of the lip print.

- Washing Too Soon: Impatience ruins projects. Wait the full 72 hours before washing.

- Ignoring the Cardboard: We have seen many hoodies ruined because the paint soaked through to the back. Always use a barrier.

Frequently Asked Questions (FAQ)

What kind of paint do you use for a kiss hoodie?

For the best results, use dedicated fabric paint. However, to get the texture of a real kiss, many people mix a "textile medium" with acrylic paint. If you use real lipstick, it must be sealed with a fabric fixative spray, or it will wash out.

How do you seal lipstick on a hoodie?

Sealing involves two steps. First, heat set the design using an iron over a protective cloth for 3-5 minutes. Second, apply a clear fabric fixative spray or a layer of transparent textile medium over the dried kisses to lock in the oil-based color.

Can I wash my kiss hoodie in the washing machine?

Yes, but only if you have properly heat-set the design. To protect it, turn the hoodie inside out and wash it on a gentle, cold cycle. Avoid hot water and harsh bleach. These can break down the color.

How to make a kiss hoodie without lipstick?

If you do not want to put paint on your lips, you can carve a potato or use a sponge cut into a lip shape. Dip the stamp into fabric paint and press it onto the hoodie. This creates a similar visual effect without the mess.

How long does it take to make a kiss hoodie?

The actual application takes about 30 to 45 minutes. However, you need to account for drying time. We recommend letting it air dry for at least 24 hours before heat setting. So, the total project time spans about two days.

Conclusion

Creating a custom garment is a rewarding experience. By following this guide on how to make a kiss hoodie, you are not just following a trend. You are using professional techniques to create something durable. The difference between a ruined hoodie and a cherished gift lies in the details. The fabric choice, the curing process, and the patience to wait before washing all matter.

At Clothing Manufacturer Ltd., we apply these principles of quality and precision to every order we produce for our 500+ successful brand partners. Whether you are making one hoodie for a loved one or planning to launch a streetwear empire in 2026, remember that quality is always the most important trend. If you find yourself needing to scale up your production, we are here to help you take your designs to the next level.