Discovering the Path to Your Ideal Custom Hoodie

Creating a custom hoodie is not just about placing a logo on it. The process consists of 3 main parts namely: Design, Sourcing, and Production. Online designers can be useful for simple items. However, brands that aim to create and sell top-quality products should work with suppliers and manufacturers. Our guide here is based on our long experiences of more than 10 years in the clothing business. It describes all the steps for making a custom hoodie that you will need to know in 2026. We will walk you from your first idea to the final product which is ready for sale.

Key Points to Focus On

- Begin with a Tech Pack: Tech packs are detailed sketches and they are the blueprints for your hoodie. They will guarantee that your manufacturer sees every detail from the stitches to the colors.

- Fabric is the Master Key: The fabric's weight (GSM) and the material used (like 100% cotton vs. a blend) determine the quality, touch, and lifespan of the hoodie.

- Method Selection is Crucial: For large production runs, it's best to use screen printing. DTG is ideally used for complex designs in smaller volumes. An embroidery machine is used to apply a logo more elegantly.

- Reference the Sample: Get a full sample before making a bulk order of the hoodies. This step helps you to avoid costly errors in fit, color, and design.

- Choose Your Partner Wisely: For a brand, the partnership with an experienced manufacturer will give you the control of quality, pricing, and full customization.

Step 1: The Finalization of Your Hoodie Design and Tech Pack

Step one in making a custom hoodie is to convert your idea into a detailed plan. A plan that serves as a production manual.

Changing the Thoughts to a Design

First, brainstorm ideas. Create a moodboard where you will stick pictures, colors, and brand styles that you find visually appealing. Then, think about where the design will be located. Is it going to be on the chest, back, sleeves, or hood? Also, consider the size of your graphic.

Design can be done online using simple online design tools which can show how your ideas would look like on a hoodie. For more technical tasks, the standard application is Adobe Illustrator. It creates vector files, which are required by the printers.

What is a Tech Pack and Why Do You Need One?

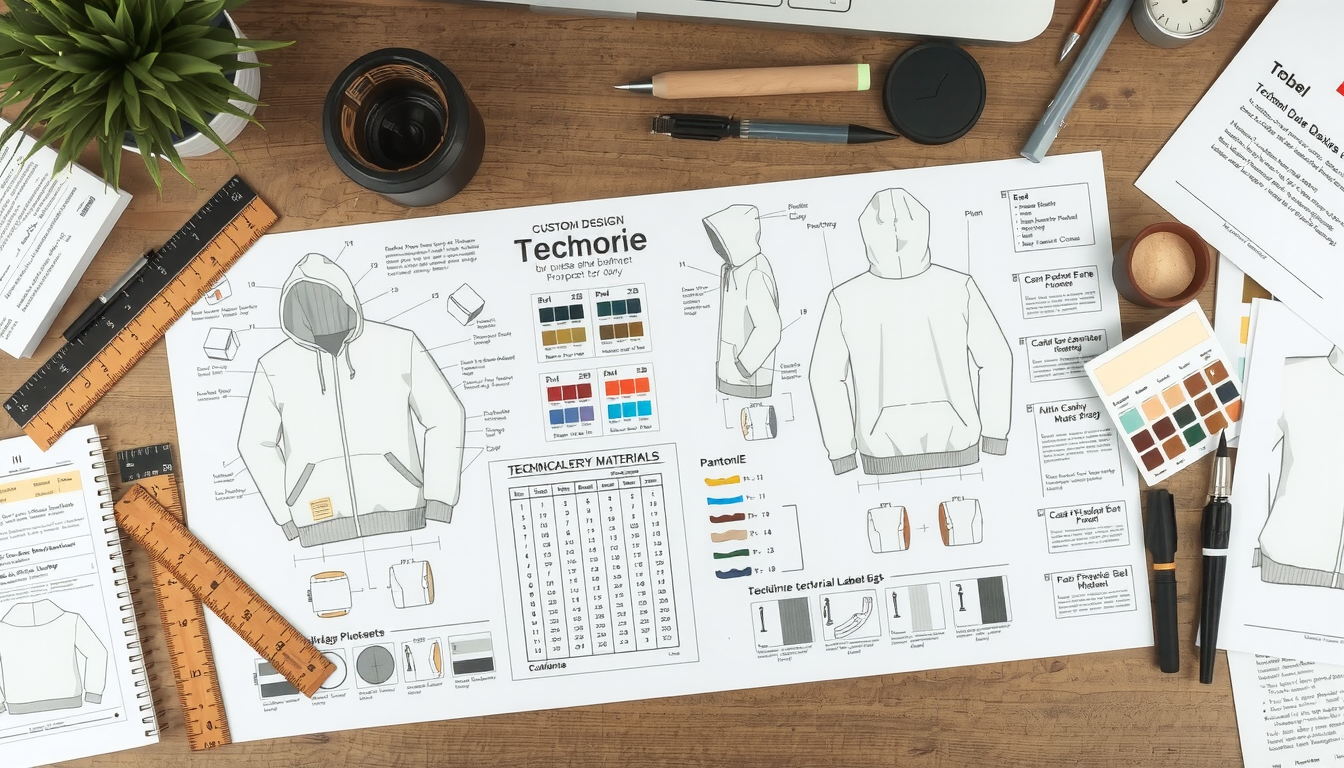

A tech pack is the most essential document in clothes manufacturing. It acts as the road map that directs the factory on how the garments should be produced. An unclear tech pack may lead to mistakes and communication problems.

A professional tech pack should always have:

- Flat Sketches: Technical illustrations of the hoodie from the front, back, and side.

- Bill of Materials (BOM): The list of all the components. Including the main fabric, ribbing, threads, zippers, and drawstrings.

- Color Specifications: Precise color codes, usually Pantone (PMS) codes. They ensure the color accuracy.

- Print/Embroidery Details: Details about the kind of customization, its exact dimensions, and the location of the design.

- Size and Grading: A size chart with measurements for your base size (like Medium). It shows how those measurements change for other sizes.

- Label and Tag Placement: Instructions for sewing in your brand labels, care labels, and hang tags.

Step 2: The Best Fabric, the Best Fit, the Best Construction

It is the design look that is important but the actual feel and quality of the hoodie will help you create loyal clients. It is about fabric and construction.

Know Your Fabric: Weight, Composition, and Feel

GSM (Grams per Square Meter) measures fabric weight. A high GSM means the material is heavier and thicker. For instance, a lightweight hoodie may weight around 280 GSM while a luxury quality hoodie may weigh 380-500 GSM or sometimes even more.

Based on the blend of the materials, the fabric is also a critical aspect. 100% Cotton gives the products a soft and breathable feeling. However, Cotton/Polyester mixed fabrics are more resilient; they are less liable to wrinkles, and they typically come in at a lower cost. Tri-blends include rayon for a softer, flowing feel.

As a manufacturer who has helped launch over 500 successful brands, we've seen a major shift in the market. Unlike other materials, organic cotton and recycled materials are not just a choice. They are becoming necessary for many customers. The demand for organic cotton and recycled materials has nearly gone up by 40% in the recent past. Our commitment to meeting this demand entails us supporting certifications like OEKO-TEX (for harmful substances) and GOTS (Global Organic Textile Standard).

Hoodie Features: Fit and Features

In addition to the fabric, the fit and small structural features are what separate a premium from a cheap hoodie. Think about what shape you'd like:

- Standard Fit: An all-time comfortable, classic fit.

- Oversized/Boxy Fit: Inspired by modern and streetwear, this style has dropped shoulders.

- Cropped Fit: A shorter body length which is a fast-trending style, especially in women clothes.

The construction of quality is the first thing generally to be spotted. A double-lined hood is generally being used in premium hoodies. Rib-knit cuffs and hems which are of high quality will help the hoodie maintain its form. The type of the drawstring is also important. Flat, wide strings with metal tips create an impression of a better quality than round unadorned ones. Also the seams stitching type such as durable flatlock seams indicates a well-made garment.

Step 3: Selecting the Best Customization Method

Having the design and the base hoodie settled, the next thing you will have to do is decide on how to apply the graphics. It is useful to consider each one separately and weigh them up against one another.

Screen Printing

Screen printing is about forcing ink through a mesh screen on the fabric. You will use a different screen for every color in your design.

- Best for: Large quantities (50 & above) and designs having fewer solid colors.

- Pros: Bulk orders are very economical. The resist and print bright colors.

- Cons: The setup cost required at the beginning is pricey. Therefore, it will not be cost-effective for small runs or designs with several colors.

Direct-to-Garment (DTG)

DTG printing is like an inkjet printer. It applies the ink directly on the fabric. Additionally, it uses a modern technique which is ideal for graphics that require a lot of detail.

- Best for: Smaller trades, one-off things, and complex photos with a multicolor palette.

- Pros: There is no minimum amount required. Incredible details can be seen.

- Cons: Each item is more expensive than screen printing at a large order. The ink might not as bright on dark-shirts as it is on light-colored ones. DTG is generally less durable over many washes.

Embroidery

Embroidery is a method of stitching the design onto the material using threads. It gives a 3D feel and a luxurious look.

- Best for: Simple designs, words, and branding on the chest or sleeve.

- Pros: It is one of the most durable branding options and looks professional. Also, it adds high perceived value.

- Cons: Unlike printing, it cannot be used for large, complex designs or photos. Additionally, it is pricier.

In the case of brands that need quick order turnaround, the standard customization methods like RushOrderTees are usually a good option.

| Customization Method | Best For | Pros | Cons |

|---|---|---|---|

| Screen Printing | Bulk orders (50+), simple graphics | Cost-effective at scale, durable, vibrant | Expensive for small runs, limited colors |

| Direct-to-Garment | Small orders, complex photos | No minimums, high detail | Less durable, less vibrant on darks |

| Embroidery | Logos, premium branding | High perceived value, very durable | Not for large designs, higher cost |

The Manufacturing Procedure by Professionals: From Sampling to Shipping

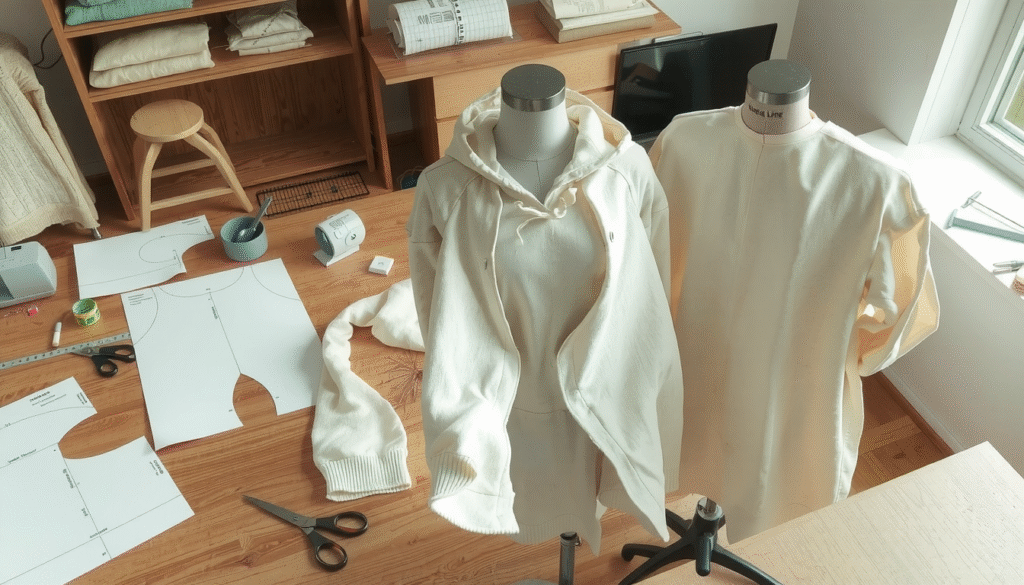

Using online designers is good for making one-off orders. However, to build a brand, you need to have wider control over the manufacturing process. This is the moment when the partnership with the manufacturer becomes vital. It is the difference between building a machine and putting a sticker on it.

Why Partner with a Manufacturer?

The biggest advantage of working directly with the factory is the ability to control everything. You get to decide almost everything including the type of fabric, specific fit, thread color, and even custom labels. Our experience with over 1000+ international fashion brands has proven this control is the only key to creating unique products. You also have the guarantee of really low prices for bulk orders. This is very important for maintaining healthy profits.

Partnering with a Professional Hoodie Manufacturer

Once you decide to make a truly custom hoodie, the process with a professional hoodie manufacturer is as follows:

- Prototyping & Sampling: We take your tech pack and create the first physical sample. You get to feel, touch and wear-test it to ensure it is perfect.

- Fabric Sourcing & Testing: We ensure the exact fabric that you've specified are of quality and color accuracy by testing and sourcing them. When you need sustainable options, our GRS certification support helps us to trace sources of certified materials.

- Bulk Production: Once you approve the sample, we will switch to full production and this means cutting the fabric for all units, sewing them, and applying your graphics.

- Quality Control: The most critical stage is this one. We implement our proprietary "5-step QC production method." Quality is checked at every single stage. This rigorous process, back to our ISO 9001 and BSCI certifications, leads to total consistency and defect elimination.

- Finishing & Packaging: Finally, additional touches are made. We sew in branded labels, attach tags, and package each hoodie for shipping.

We have witnessed clients skip the sampling step to save time. However, this almost always leads to bigger issues and costs later. Having a perfect sample will be the best asset you could ever have for a successful production run.

Avoiding Common Pitfalls with a Custom Hoodie

With over 10 years in clothing production, we've seen every possible mistake. Learning how to make a custom hoodie also means learning what to avoid. Here are the most common pitfalls and how to prevent them.

-

Pitfall 1: Low-Resolution Artwork

-

Problem: Your design looks unclear, jagged, or pixelated when printed.

-

Solution: Always submit your artwork in the vector format (.ai, .eps, .svg) or as a high-resolution raster file (.png, .psd) at 300 DPI (dots per inch) at the final print size.

-

Pitfall 2: Ignoring Fabric Shrinkage

-

Problem: Your perfectly fitting hoodie shrinks after the first wash, which leads to unsatisfied customers and bad reviews.

-

Solution: Use pre-shrunk fabrics. Cotton/polyester blends also do not shrink as much as 100% cotton. Also, don't forget to ask your manufacturer for wash test results pertaining to the specific fabric.

-

Pitfall 3: Poor Communication with Your Supplier

-

Problem: Small misunderstandings in the tech pack result in a batch of hoodies that are the wrong color, size, or design.

-

Solution: Communicate every detail clearly. Do not make any assumptions. This is the reason why partnering with a clothing manufacturer that has set protocols for communication is so critical for a brand to succeed.

-

Pitfall 4: Unrealistic Budget and Timelines

-

Problem: You rush the process to meet a deadline. This will compromise the quality and cause mistakes.

-

Solution: Schedule activities in advance. In addition to the sampling time, include time for changes, production, and international shipping. While tools like Owayo's 3D Designer are helpful for planning a design, remember professional production is a multi-stage process that can't be rushed.

Frequently Asked Questions (FAQ)

What is the minimum order quantity (MOQ) for custom hoodies?

This varies significantly. Online print-on-demand services have no minimum. However, to access better pricing and full customization with a manufacturer like us, MOQs typically start around 50-100 units per design.

How much does it cost to make a custom hoodie?

The cost depends on quantity, hoodie quality, fabric, and customization type. A single DTG-printed hoodie might be $40-$60. A bulk order from a manufacturer could bring the per-unit cost down to $15-$25, depending on complexity.

How long does the process take from design to delivery?

For a single online order, it can be 1-2 weeks. For a full manufacturing run, you should budget 4-8 weeks. This includes sampling (1-2 weeks), bulk production (2-4 weeks), and shipping.

Can I provide my own blank hoodies for printing?

Most online printers and manufacturers do not accept customer-supplied garments. This is because we cannot guarantee the quality of the blank or how it will react to our printing or embroidery processes. We control quality by sourcing the garments ourselves to ensure a perfect final product.

What's the difference between a custom hoodie and a private label hoodie?

A "custom hoodie" can be a one-off design printed on a stock blank hoodie. "Private label" means creating a hoodie that is fully unique to your brand. This includes custom fabric, a specific fit, and your own branded tags and labels. This is the comprehensive service we specialize in for building serious fashion brands.